HOME > Research Activities > Research Updates >

In 2013 the Large Helical Device (LHD) succeeded in maintaining a plasma of 23,000,000 degrees for forty-eight minutes. This is a world record for long-term maintenance of a high-performance plasma. However, for achieving fusion energy it is necessary to maintain a plasma at more than 100,000,000 degrees throughout one year. However, thanks to having succeeded in achieving the world’s longest maintenance of a plasma, we have come to understand one of the ideas for continued maintenance of plasma extending over a long period of time. In our research, when we encounter a wall, it is always necessary to retrace the path and consider

- Why did the experiment not go well, and find the reasons;

- For the experiment to go well, consider what should be done; and

- Try the ideas that one has thought of.

Today, let us together retrace the path, in order, step-by-step, that aims to achieve even still longer extended maintenance of a plasma.

Step 1: When investigating why it is difficult to achieve long-term maintenance over many hours of a high-performance plasma, one reason is that the composite sediment layer, which is formed on the vacuum vessel wall, exfoliates from the vacuum vessel and lowers the temperature of the plasma.

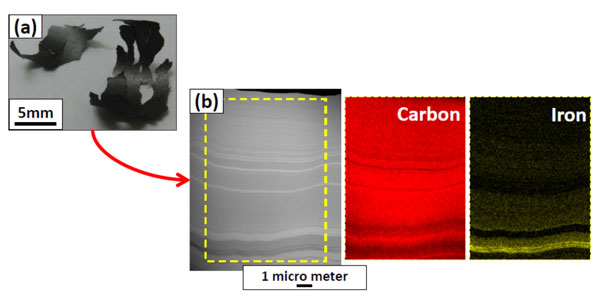

Here, let us explain the composite sediment layer. The wall of the LHD is composed of stainless steel and carbon. Wall surface material is removed through particle bombardment with the wall. Matter removed from the wall accumulates in the place where it lands, and an accumulation layer is formed. This layer, because it is a composite of carbon and iron (a component of stainless steel) and has been formed, is called the composite sediment layer. The composite sediment layer has a size of one micrometer (1/1000 of a millimeter), and each layer has a size of from 10 to 100 nanometers (one nanometer is 1/1,000,000 of one millimeter). Even at this size, depending upon the condition, the sediment layer is focused upon as a factor which influences plasma performance. From various places on the wall surface are torn debris from the composite sediment layer. Using an electron microscope, those characteristics have been investigated. (See back number 191.)

This time, in order to clarify the relation between the composite sediment layer and extended duration maintenance of plasma, we investigated the LHD vacuum vessel wall surface soon after achieving the world record noted above, and determined the location of the composite sediment layer, which was one of the causes of plasma termination. Then, from that region we cut debris out of the composite sediment layer, and, having analyzed in detail the microstructure and its composition, when seen in full carbon is the main component, but at each layer the ratio of carbon and iron varies. We learned that those layers lie one atop another, and have a complicated structure similar to a mille-feuille pastry. (In a mille-feuille pastry, each layer is made from a different ingredient.) Moreover, to investigate the degree of strength of that composite sediment layer we used a dynamic ultra-micro hardness tester and learned that this mille-feuille pastry structure was the cause of the peeling. When one stabs a mille-feuille pastry with a fork it easily collapses. Similarly, the composite sediment layer, too, easily collapses when only a minute force is added from outside although the scale is extremely small. The volume of the LHD plasma is thirty cubic meters. It is quite strange that something as small as a one micrometer composite sediment layer should control the maintenance of a plasma.

2. Next, how can we prevent the generation of such a composite sedimentary layer and peeling? That is, let us consider the idea for maintaining the plasma over an extended duration of time. The answer is extremely simple. If the material for the fusion reactor wall is to be composed entirely from one kind of material, then the mille-feuille pastry sedimentary layer structure will not be generated. Moreover, if that material is a strong material which plasma cannot scrape, that would be perfect.

3. We would like to test an idea. However, an excellent material that can respond in all locations of the fusion reactor wall has not yet been found. For that reason, for realizing still longer extended duration plasma maintenance we are but halfway there. To test an idea that we have, at the National Institute for Fusion Science we are advancing in the development of composite materials that are strong and tough, which combine metals and ceramics, and we are affixing high melting point metal tungsten to the surface of carbon materials and copper alloys, which are strong against heat.

Please look forward to our next stage.

a) Photograph of composite accumulation layers that caused termination of extended duration plasma maintenance. Similar to slough, brittle peelings are detaching and falling.

b) Cross-section of the composite accumulation layer (a) was observed by transmission electron microscope (TEM). Using a device called Focused Ion Beam Processing Observation Device (FIB), we conducted ultrafine minute processing to make a sample that can be observed by TEM. This indicates the distribution of carbon and iron in the inner area enclosed by yellow dashed lines. To the extent that the red and yellow colors are thick, this means that the quantities of carbon and iron are numerous. We can see that the carbon and iron are becoming like the mille-feuille pastry in the layers being one upon another. We learned that a composite sediment layer with such a composition and structure is extremely brittle.