HOME > Research Activities > Research Updates >

Plasma-Material Interaction Investigated by Electron Microscope: The Discovery of the Effect of Crystal Orientation

In the future fusion reactor, tungsten, which is hard and has a high melting point, is anticipated as the plasma facing material. At the National Institute for Fusion Science, in order to clarify what type of effects upon tungsten will result from plasma, we expose plasma to the tungsten surface and analyze the microstructure of the tungsten surface by electron microscope. In addition, we undertake simulation research utilizing the supercomputer. (For details, see back number 201.) Here, we introduce newly-discovered phenomena regarding influences upon tungsten at the time of helium plasma exposure to tungsten.

In a magnetic field confinement device, using a magnetic field container we seek to prevent the high-temperature plasma from directly touching a surrounding wall (below, as “wall”). However, there also are plasma particles that escape from the magnetic field container and strike the wall. In the future fusion reactor, helium will be generated through the fusion reaction of deuterium and tritium (both are isotopes of hydrogen). From the view that the helium amount of as much as 10% will be present in the plasma, it is possible that hydrogen isotopes and helium plasma will strike the wall, affect the wall material, and cause changes in the characteristics of the material. Further, impurities are generated from the wall and affect the plasma, the hydrogen isotopes and the helium that were injected into the wall are again released from the wall, and sometimes return to being plasma. In this way, this joint influence between the plasma and the wall is called “plasma wall interaction,” and is becoming an important research field. In this research, we focused upon helium, which is known to greatly influence metal materials. In the fusion reactor, because the wall temperature is thought to reach from 500 to 700 degrees Celsius, we investigated the influence of helium plasma exposure toward tungsten in the above-mentioned temperature range.

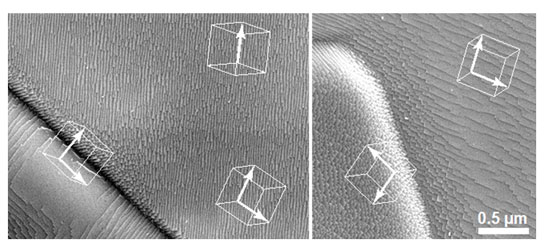

When exposing helium plasma to tungsten, inside the tungsten helium accumulates, a small helium bubble of approximately several nanometers in size is formed. (A nanometer is 1/1,000,000 of a millimeter.) The place where the bubble is formed is at a depth of 10 nanometers from the surface. When the exposure dose becomes high, a bubble is generated, and the structure of the tungsten surface changes. In particular, in a region where the temperature exceeds 900 degrees Celsius, it is known that a structure called fuzz which is similar to wool will be formed. Here, in a region where the temperature is less than 900 degrees Celsius we have newly learned that a nanoscale undulating structure will be formed on the surface.

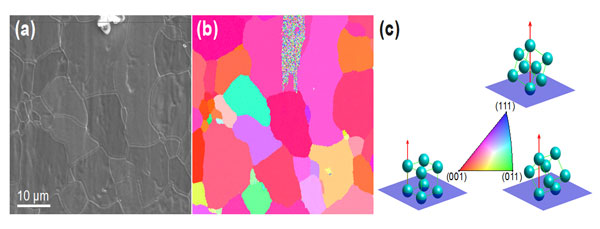

A metal such as tungsten may seem to be uniform when viewed, but it is composed of grains called crystal grains which range in size from 1,000 parts per millimeter to ten parts per millimeter. Inside one crystal grain, the crystal orientation (the direction in which the atoms are aligned) is aligned in the same direction, and in a different crystal grain the crystal orientation differs. When we analyzed the structure of the newly discovered undulating structure using a scanning electron microscope (SEM), we learned that the direction and intervals of the undulating structure differed depending upon the crystal grain. This indicates that the undulating structure is influenced depending upon the difference in the crystal orientation. Further, in order to investigate up to what depth the undulating structure is being formed, we cut the surface that the plasma touched using a Focusing Ion Beam (FIB) and observed the cross-section of the surface structure using a Transmission Electron Microscope (TEM). As a result, we learned that the height of the undulating wave structure was approximately 8 nanometers, and it was the same as the depth disturbed due to helium irradiation to the tungsten crystal. Moreover, the surface after helium plasma irradiation varied in height depending upon each crystal grain. And we learned that the speed at which the surface suffers wear due to strikes by the helium plasma differs depending upon the crystal orientation.

These discoveries indicate that depending upon the crystal orientation the effects differ caused to the tungsten surface by the exposure of helium plasma. And they provide important information from the perspectives of impurities mixing into plasma and of the improvement of material characteristics.

In the future, we will undertake plasma irradiation experiments and analysis, and together with investigating these phenomena in detail we will advance our research on clarifying the mechanisms of these phenomena.

Figure 1: (a) is an image of the tungsten surface by the scanning electron microscope (SEM). Tungsten is composed of crystal grains, and a cross-section of its surface, which is irregular, resembles a map of the world. The horizontal line in the lower left indicates 10 micrometers in the SEM image (a micrometer is 1/1,000 of one millimeter). (b) is the two-dimensional distribution of the crystal orientation, and was investigated using the electron backscatter diffraction pattern (EBSD) of the electron beam. The difference in color is responding to the crystal orientation in (c), and we now understand that the crystal orientation varies depending upon the crystal grains. (001), (011), and (111) are the indices expressing the direction of the lined-up atoms with crystal structures.

Figure 2: Image from SEM showing the undulating surface structure that was formed when helium is irradiated to the tungsten. Showing the enlargement of the crystal grain boundary. The direction and intervals of the undulating structure differ depending upon the crystal grain. The cube shown in the figure displays the crystal direction (See figure 1(c).), and the thick arrow is displaying the direction of (001). We can know that the undulating structure is aligned along a particular direction shown by the large arrows.