HOME > Research Activities > Research Updates >

Development of the Cryogenic Adsorption Pump for Evacuating System

In the Large Helical Device we produce plasma by introducing hydrogen gas into the vacuum vessel. Because the remaining hydrogen gas that did not become plasma reduces the plasma temperature, it must be evacuated to outside. Therefore, the remaining hydrogen gas is collected in one place and evacuated by pump. Here, we will introduce the “Cryogenic Adsorption Pump” which we have developed for the evacuating system.

The Cryogenic Adsorption Pump (hereafter as cryo-adsorption pump) is a pump that uses carbon, and while small in size it has the special characteristic of being able to evacuate large amounts of exhaust. Carbon is a charcoal with numerous small holes that are but nanometers in size, and is also used in houses as a deodorizer. Carbon has the effect of adsorbing substances in the air even at normal temperatures. But when cooled to below -250 degrees adsorption efficiency of hydrogen gas significantly improves. Inside the cryo-adsorption pump granular carbon affix themselves tightly to extreme low-temperature panels made from copper. The carbon is cooled through those panels, and the hydrogen gas is effectively evacuated.

In cryo-adsorption pumps utilized to date, in order to affix the carbon to the extreme low temperature panels, an organic adhesive agent (similar to powerful “glue”) had been used. However, with this adhesive agent, due to degradation by aging, there were the problems of carbon sometimes exfoliating and of impurities being expelled from the adhesive. We could not directly use these pumps inside the LHD vacuum vessel, which requires a high degree of vacuum. Thus, at the National Institute for Fusion Science (NIFS), in cooperation with companies, we conceived a breakthrough method for affixing carbon and extreme low-temperature panels using metal. Through this new method for inorganic adhesives, we have overcome issues heretofore unsolved, and have succeeded in developing a cryo-adsorption pump which makes it possible to utilize inside the LHD’s vacuum vessel.

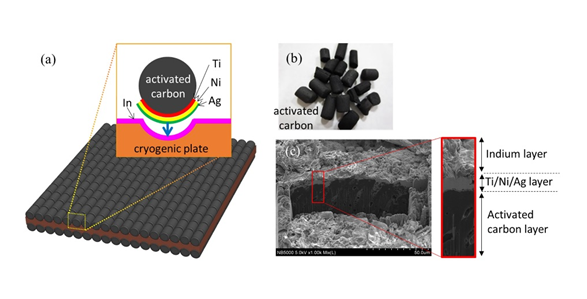

We use the metal indium which has a melting point at the low temperature of 156 degrees as the adhesive. Indium can be adequately affixed to extreme low-temperature panels made of copper. However, its compatibility with activated carbon is poor, and merely by placing it in contact with carbon achieving adhesion was difficult. In order to strongly affix activated carbon to the metal, that is, for carbon to fit naturally into metal, it is necessary that metal enters the many holes in the activated carbon. Thus, on the surface (adhesion side) of the extreme low temperature panel surface of the activated carbon, we used the “sputtering method” to make a membrane of other metal than indium. The “sputtering method” releases atoms and molecules of a metal toward the substance and produces a delicate membrane on the surface of the substance. Through this method, the atoms and molecules of the metal invade the nano-level holes in the activated carbon. The metal enters in a manner similar to the roots of a tree, and we are able to make a metal membrane that attaches strongly to the activated carbon. Moreover, investigating the compatibility among various metals, we produced a three-layer membrane from three different metals and inserted the membranes between the carbon and the indium. First, in the first layer to come into contact with the carbon we deposited titanium, which has good compatibility with carbon, and in the third layer to come into contact we deposited silver, which has good compatibility with indium. Then, in the second layer between the first layer with titanium and the third layer with silver we deposited nickel, which has good compatibility with titanium and silver. The nickel in the second layer avoided permeation by the indium to the silver, and performed the role of a barrier. In this way, we established a bonding method that enables strong adhesion between the carbon and the extreme low-temperature panel by making metal membrane layers with good compatibility using the sputtering method. Thus we succeeded in the inorganic adhesion between the carbon and extreme low temperature panels which heretofore had been difficult.

Further, we selected the most appropriate carbon for evacuating hydrogen gas from several varieties of carbon. Moreover, in order to greatly improve the efficiency of gas exhaust we optimized the path that guides the hydrogen gas to the microscopic holes based upon computer simulations. We installed the new cryo-adsorption pump, which was developed using inorganic adhesion from these improvements, to the vacuum vessel of the LHD. The results of evacuating tests showed an increase in the pumping speed that was seven times larger. This new pump, by controlling the hydrogen gas flow, is expected to greatly contribute to research in long-term maintenance of high-temperature plasma. Moreover, the inorganic adhesion method has now been patented as “Cryo-adsorption panel and its manufacturing method, and the vacuum device which uses the method” (patent number 6021276), and because this method is applicable to existing devices, we also anticipate wide-ranging applications in manufacturing equipment and in the industrial world not only for the high-temperature plasma experimental device but also for semi-conductors and liquid crystal displays.

Image: (a) is a schematic image showing the inorganic adhesion method. Above the activated carbon layer are three types of metal layers formed (titanium (Ti), nickel (Ni), and silver (Ag)) and using indium (In) carbon is affixed to an extreme low-temperature panel. Alongside a groove cut in the extreme low-temperature panel, by (b) lining up pellet-shape activated carbon with the same diameter, the largest cooling area of the activated carbon and the higher-density activated carbon are depicted. And (c) is a photograph of a fault in the surface of an activated carbon. We can see on the rough surface of an activated carbon that a metal layer is carving into the surface.