HOME > Research Activities > Research Updates >

In the Large Helical Device (LHD), after having evacuated the vacuum vessel by pump, we introduce hydrogen gas and produce a plasma. Evacuation is undertaken by a pump placed outside of the vacuum vessel (this is called the primary pump). But also in the vacuum vessel is an evacuation pump called the “Cryo-adsorption Pump.” The Cryo-adsorption pump evacuates hydrogen gas by adsorbing the gas in the activated carbon that has been cooled at an extreme low temperature. The National Institute for Fusion Science (NIFS), working together with companies, has developed a high-performance cryo-adsorption pump that can be placed inside the vacuum vessel using a revolutionary production method. (For details, see back number 293.) Here, we will introduce evacuation performance of this cryo-adsorption pump that has been achieved in recent experiments.

First, we will explain why an evacuation pump is necessary inside the vacuum vessel. In the LHD, in order to efficiently collect impurities and hydrogen gas that did not become plasma we have placed a device called a divertor in the vacuum vessel. However, the hydrogen gas particles that were collected return to a plasma before too long. This is called particle recycling. By lowering the particle recycling (that is, reducing the number of particles that return to being a plasma from the divertor) we have learned that plasma performance improves, and that it becomes easier to control plasma density. In order to reduce particle recycling, we must effectively evacuate the hydrogen particles that have accumulated on the divertor. And in order to achieve high efficiency evacuation, it is necessary to install a high-performance evacuation pump on the divertor in the vacuum vessel.

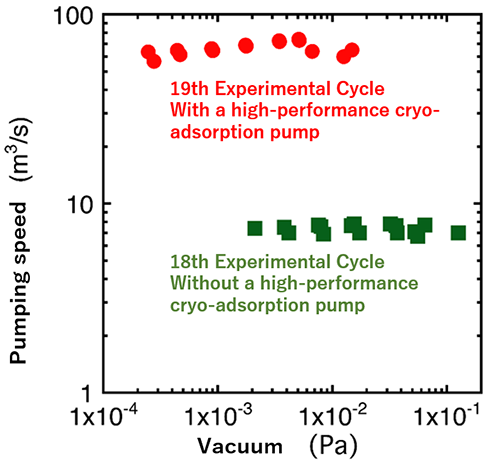

Thus, at NIFS we have developed a high-performance cryo-adsorption pump that can be attached to the divertor. In the LHD, the divertor is attached between the plasma of the doughnut configuration and the vacuum vessel wall. On the inner-radius side of the doughnut is attached the cryo-adsorption pump. From before the beginning of the 19th cycle of plasma experiments (February 8, 2017-August 3, 2017), when we tested the evacuation efficiency of the cryo-adsorption pump by introducing hydrogen gas in the LHD, compared to the 18th Experimental Cycle we achieved a pumping speed of approximately seven times higher. That speed is a value that approaches the pumping speed of the LHD’s vacuum pump. Further, the pumping capacity was approximately fifteen times greater. This capacity is equal to 20,000 deuterium pellets. (A pellet is a small grain of ice. In the LHD, the pellet is used as one means of providing fuel.) This is approximately twenty days of use in the LHD’s high-density plasma experiments. In this way, we confirmed the value at which pumping speed and pumping capacity will contribute to plasma improvement.

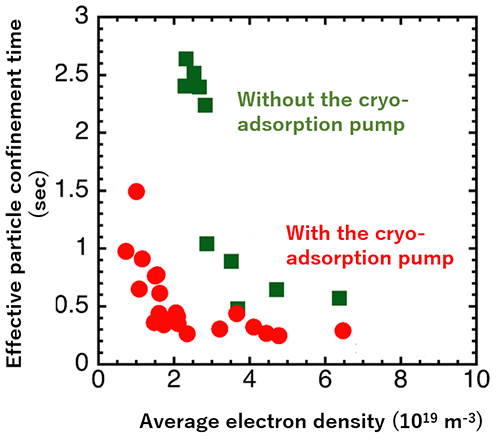

In the 19th Experimental Cycle, we conducted plasma experiments using the improved cryo-adsorption pump. As preliminary results, under the same fueling conditions as heretofore, we have observed that plasma density decreases due to the cryo-adsorption pump, and that when halting the fuel supply the speed at which plasma density decreases increases. This result is due to the high-performance evacuation effect of the cryo-adsorption pump installed to the divertor. And this indicates that we have achieved the so-called “low recycling condition” in which the number of particles that return to the plasma is few. Thus, we may conjecture that this contributes to the improvement of the plasma performance. In the future, we plan to investigate in further detail regarding the cryo-adsorption pump’s influence upon plasma confinement and the controllability of plasma density

Image 1: Results of evacuation tests in LHD. A square in the case of without a high-performance cryo-adsorption pump (18th Experimental Cycle), and a circle in the case of high-performance cryo-adsorption pump installed to the divertor (19th Experimental Cycle). According to the high-performance cryo-adsorption pump, pumping speed increased by approximately seven times.

Image 2: The density dependence of effective particle confinement time as obtained during the 19th Experimental Cycle. When the effective particle confinement time is short, this means that the speed of the plasma-density-decrease after halting the supply of fuel is fast. The circles indicate that the cryo-adsorption pump is present, the squares indicate that the cryo-adsorption pump is not present.